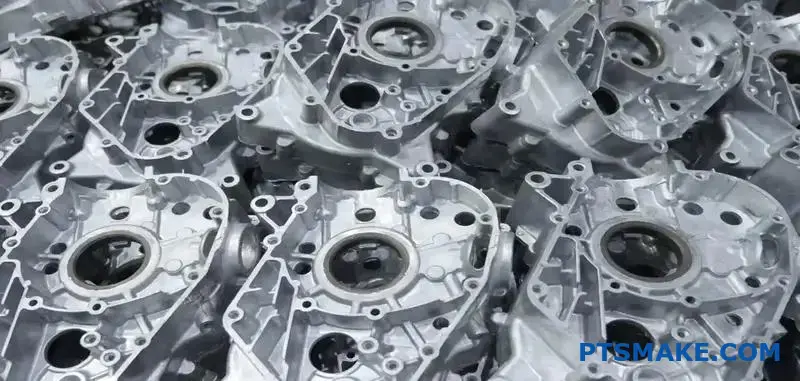

How Foundry Services Enhance Production Efficiency and Top Quality in Industrial Applications

Foundry solutions play an essential duty in enhancing production effectiveness and quality across various commercial applications. By applying innovative steel casting strategies, these solutions assure elements are produced with accuracy and consistency. This not just lowers preparations yet additionally decreases waste, promoting far better partnership in between shops and makers. The influence of top notch parts on operational performance increases essential questions concerning the future of commercial production. What technologies lie in advance in this developing landscape?

The Duty of Foundry Solutions in Streamlining Production Processes

Factories often provide expertise in alloy advancement, enabling makers to make use of sophisticated materials that enhance product performance. The collaboration in between factories and makers cultivates a much better understanding of production needs, causing enhanced procedures and improved product layouts. By leveraging factory solutions, manufacturers can attain better versatility, adapt to altering market demands, and preserve competitiveness in the sector. In general, the role of factory solutions is crucial in facilitating an extra cost-effective and efficient manufacturing landscape.

Advanced Technologies in Shop Procedures

Cutting-edge modern technologies are changing factory operations, significantly enhancing efficiency and accuracy. Automation plays a vital role, with robotic systems simplifying repeated jobs such as molding and product handling. Additionally, advancements in computer-aided layout (CAD) and computer-aided production (WEBCAM) systems enable factories to develop intricate geometries with higher precision and lowered material waste.

The assimilation of fabricated knowledge (AI) and equipment understanding improves top quality control by monitoring procedures in real-time and predicting possible issues before they occur. The use of innovative products, such as lightweight alloys and composites, better boosts the efficiency qualities of cast items.

3D printing technology is changing prototyping and tooling, enabling for rapid customization and lowered lead times. Jointly, these innovative technologies not only raise manufacturing effectiveness however additionally guarantee that the end products satisfy strict quality requirements, placing factories at the leading edge of contemporary industrial applications.

Lowering Lead Times Via Efficient Foundry Practices

Effective foundry methods play a necessary function in lessening lead times within manufacturing environments. By implementing structured production processes and advanced organizing strategies, producers can enhance process and enhance resource appropriation. These renovations not only accelerate result yet additionally add to general functional effectiveness.

Structured Manufacturing Processes

Improving production procedures is crucial for minimizing preparations in the production market. Reliable shop practices, including enhanced operations and resource administration, play an important function in attaining this goal. By minimizing waste and enhancing communication amongst groups, foundries can considerably improve their functional performance. The implementation of standard treatments also adds to regular top quality and faster turnaround times, enabling suppliers to react even more promptly to market demands. Furthermore, the combination of advanced modern technologies, such as automation and real-time monitoring systems, assists in identifying bottlenecks and assisting in timely interventions. On the whole, an emphasis on structured production processes not just accelerates lead times however also improves the total competition of industrial applications, ensuring that products satisfy customer expectations properly.

Advanced Organizing Techniques

Effective manufacturing procedures naturally lead makers to explore advanced scheduling strategies as a way to even more minimize preparations. By utilizing advanced algorithms and software application, foundries can optimize operations, straightening production timetables with need projections and resource availability. Strategies such as Just-In-Time (JIT) organizing lessen supply prices while making sure timely product distribution, therefore enhancing operational efficiency. In addition, integrating real-time information analytics permits factories to anticipate potential hold-ups and change schedules proactively. This adaptability not just improves procedures however additionally enhances overall performance. Collective planning with suppliers and customers can promote a much more integrated supply chain, further minimizing lead times. resource Eventually, these sophisticated organizing techniques equip factories to accomplish higher effectiveness and exceptional high quality in their manufacturing procedures.

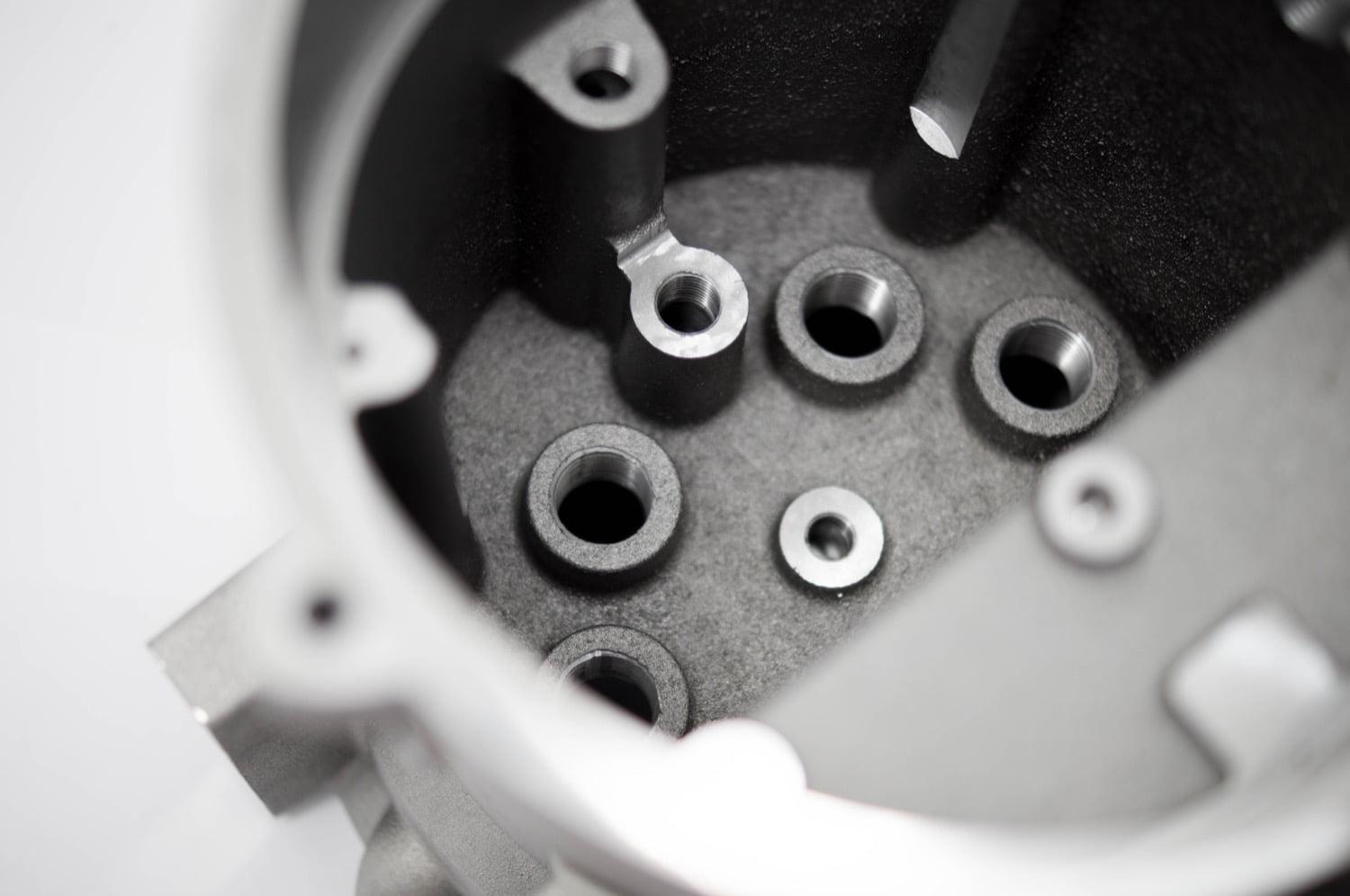

Ensuring Accuracy and High Quality in Steel Spreading

Guaranteeing precision and quality in steel spreading requires a thorough method that includes every stage of the manufacturing procedure. This process begins with careful layout and design of the mold and mildews, assuring they can hold up against the liquified metal's temperature and stress. The selection of high-quality raw materials is necessary, as contaminations can compromise the end product.

When the products are prepared, exact temperature level control throughout melting and pouring is fundamental to accomplish the preferred homes in the actors metal. Keeping an eye on solidification and air conditioning prices further warranties dimensional precision and surface area coating.

Quality guarantee practices, such as non-destructive testing and evaluation, are important to recognizing flaws early in the procedure. Aluminum Foundry. In addition, employing experienced employees who understand the subtleties of metal spreading adds significantly to maintaining high requirements. On the whole, these methods jointly improve the reliability and efficiency of cast elements in numerous industrial applications

Reducing Waste and Maximizing Resource Use

Furthermore, reusing scrap steel within the factory itself can substantially reduce waste, changing spin-offs right into functional sources. Lean making concepts also add to squander decrease by improving procedures and getting rid of unnecessary steps, leading to extra reliable procedures.

Routine upkeep of tools warranties peak performance, avoiding failures that can result in thrown away products. By focusing on these methods, shops not just minimize expenses however also contribute to sustainable practices, aligning with the expanding demand for ecologically accountable manufacturing techniques in commercial applications.

The Affordable Advantage of High-Quality Elements in the Market

High-quality elements supply a substantial affordable advantage in the foundry market, where accuracy and resilience are vital. Makers that prioritize premium products and workmanship can boost item performance and integrity, causing boosted customer complete satisfaction. This advantage is specifically obvious in sectors such as automobile and aerospace, where part failing can have devastating effects.

Additionally, high-grade components usually result in reduced maintenance expenses and prolonged product lifespans, which can be appealing marketing points for possible customers. As market needs grow for efficient and lasting innovations, the focus on high quality ends up being much more vital. Business that spend in top quality shop solutions not only boost their production procedures yet likewise separate themselves from rivals that might compromise quality for price financial savings. The commitment to high-grade parts inevitably equates into a more powerful market placement and lasting organization success.

Often Asked Questions

What Kinds of Materials Do Foundry Provider Typically Collaborate With?

Factory services typically deal with metals such as light weight aluminum, brass, steel, and iron, along with different alloys. They also deal with materials like porcelains and compounds, dealing with varied commercial requirements and specifications in manufacturing procedures.

Just How Do Factory Services Impact Overall Supply Chain Management?

Foundry solutions considerably enhance supply chain Visit Website management by streamlining material sourcing, lowering lead times, and ensuring constant high quality. Their ability to provide customized remedies promotes collaboration amongst stakeholders, eventually improving general operational efficiency and responsiveness in production.

What Industries Advantage Most From Foundry Providers?

Industries such as auto, construction, consumer, and aerospace goods substantially take advantage of shop services. These sectors count on accuracy castings to meet stringent quality requirements and improve their total manufacturing procedures and item efficiency.

Are Foundry Services Sustainable and Ecologically Pleasant?

Shop solutions can be ecologically pleasant and lasting, especially when employing advanced innovations and procedures - Aluminum Casting Company. Advancements such as recycling products, lowering discharges, and enhancing power use contribute to lessening their eco-friendly influence in commercial applications

Just How Can Companies Pick the Right Factory Company?

Business can pick the appropriate shop company by assessing competence, production capabilities, top quality accreditations, technology used, consumer testimonials, and sustainability practices while making sure alignment with their specific task requirements and long-term company objectives.

Shop solutions play a necessary duty in enhancing manufacturing performance and top quality across various commercial applications. The cooperation between makers and foundries cultivates a better understanding of manufacturing needs, leading to optimized procedures and enhanced item designs. Effective foundry practices play an important role in lessening lead times within production settings. By utilizing sophisticated algorithms and software, factories can optimize workflows, straightening manufacturing routines with need projections and resource accessibility. Companies that invest in top notch shop services not just improve their production processes but additionally differentiate themselves from rivals who may sacrifice top quality for cost savings.